Batch machining facilities include:–

- C.A.D./ C.A.M. design facilities allows 3D machining from models using 3 axis mills

- Autocad 2005

- Mastercam Version X

- C.N.C. milling

- Mazak Integrex i 200 (Renishaw probes)

- Mazak Nexus 3 (Renishaw probes)

- Matsuura twin pallet model RA-IG 500mm X 400mm X 450mm machining envelope

- 1 off VM3500 XYZ 3 axis mill 450mm x 750mm x 550mm envelope

- 2 off Pro 2,000 XYZ 2 axis mill 760mm x 250mm

- New V40M Vertical Machining Centre x=1020mm y=510mm z=610mm fitted with 4th axis

- C.N.C. Turning

- 1 off Mazak slant turn 20 live tooling 52mm bar capacity

- 1 off Mazak QTN250 2MY 12 station live tooling, 80mm bar capacity, C and Y axis

- 1 off XYZ Vulcan 150 with bar puller 38mm bar capacity

- Leadwell T7 CNC lathe with 65mm diameter bar feeder

- Various manual Colchester lathes

- General Equipment

- 1 off Rascamat 400 pneumatic tapping machine

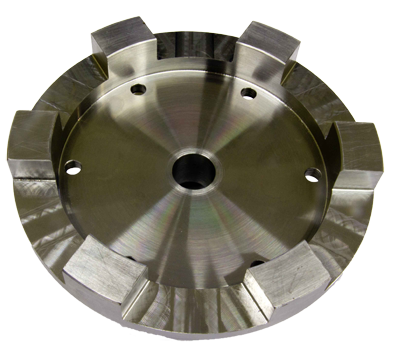

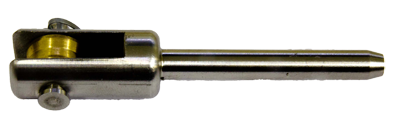

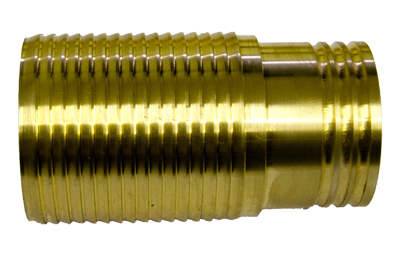

The small batch machine shop supplies small batch machined items, jigs and fixtures, to aerospace, industrial, and oil industries, batch sizes range from 1 -10k parts M/C fitted with Renishaw tool and spindle probing systems.

The company is situated in the heart of Gloucestershire, where the U.K. aerospace industry was founded. It is supported by a local network of finishing shops, which means we can offer a full range of finishes.